Six Sigma : Define : 4 : Map Process 5 Refine Project Scope

Benefits of Process Pareto Diagrams Mapping SIPOC Definition of Project Scope

4 : Map ProcessBenefits of Process Mapping

•Provides a visual representation of the process

•Allows flexibility in levels

•Demands verification and objectivity–Hands-on exposure to local activities

•Identifies rework loops and redundancies

•Gives insight into bottlenecks, cycle times and inventory•Serves as a training and orientation tool

•Identifies non-value added steps

•Helps identify when and where to collect data•Identifies where different work teams use different processes

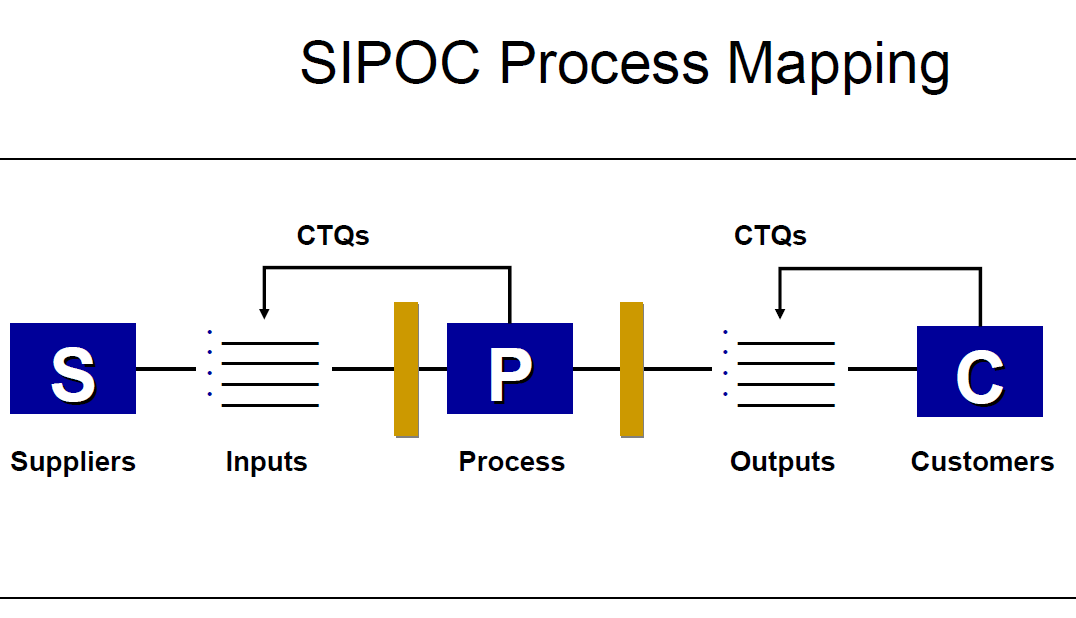

SIPOC process map is designed to be high level process view with4-7 steps displayed

Simon suggests the following steps for the developing of a SIPOC diagram:

1.Have the team create the process map. A meeting room with wall space can be used to display the process steps. Cards can be used to map out the process before finalizing a map

2. The process may have four to five key steps. How is the raw material or product transformed?

3. List the outputs of the process. What is the end result, product/service of this process?

4. List the customers of the output of the process. Who is the user of the end result of the process?

5. List the inputs of the process. Where do the materials come from?

6. List the suppliers of the process. Who are the key suppliers?7. As an optional step, identify some preliminary requirements of the customers.

8. Involve the team leader, champion, and other stakeholders for verification of the project.

Here is how you can do it:

5 Refine Project ScopeDefinition of Project Scope

Project scope is the extent to which variables or factors will be measured and analyzed, in order to target specific areas for process improvements.

Pareto Diagrams

Pareto diagrams are very specialized forms of column graphs. They are used to prioritize problems ( Or opportunities) so that the major problems (or opportunities) can be identified. Pareto diagram can help Six Sigma teams get a clear picture of where the greatest contribution can be made.

Pareto diagrams are used to

•Analyze a problem from a new perspective

•Focus attention on problems in priority order

•Compare data changes during different time periods

•Provide a basis for the construction of a cumulative line

4 : Map ProcessBenefits of Process Mapping

•Provides a visual representation of the process

•Allows flexibility in levels

•Demands verification and objectivity–Hands-on exposure to local activities

•Identifies rework loops and redundancies

•Gives insight into bottlenecks, cycle times and inventory•Serves as a training and orientation tool

•Identifies non-value added steps

•Helps identify when and where to collect data•Identifies where different work teams use different processes

SIPOC process map is designed to be high level process view with4-7 steps displayed

Simon suggests the following steps for the developing of a SIPOC diagram:

1.Have the team create the process map. A meeting room with wall space can be used to display the process steps. Cards can be used to map out the process before finalizing a map

2. The process may have four to five key steps. How is the raw material or product transformed?

3. List the outputs of the process. What is the end result, product/service of this process?

4. List the customers of the output of the process. Who is the user of the end result of the process?

5. List the inputs of the process. Where do the materials come from?

6. List the suppliers of the process. Who are the key suppliers?7. As an optional step, identify some preliminary requirements of the customers.

8. Involve the team leader, champion, and other stakeholders for verification of the project.

Here is how you can do it:

5 Refine Project ScopeDefinition of Project Scope

Project scope is the extent to which variables or factors will be measured and analyzed, in order to target specific areas for process improvements.

Pareto Diagrams

Pareto diagrams are very specialized forms of column graphs. They are used to prioritize problems ( Or opportunities) so that the major problems (or opportunities) can be identified. Pareto diagram can help Six Sigma teams get a clear picture of where the greatest contribution can be made.

Pareto diagrams are used to

•Analyze a problem from a new perspective

•Focus attention on problems in priority order

•Compare data changes during different time periods

•Provide a basis for the construction of a cumulative line